Exploring the Benefits and Considerations of Steel Roofing

Outline

– What steel roofing is and where it excels

– Performance and durability in varied climates

– Energy efficiency and environmental considerations

– Costs, value, and budgeting for the long term

– Installation, maintenance, and a practical decision checklist

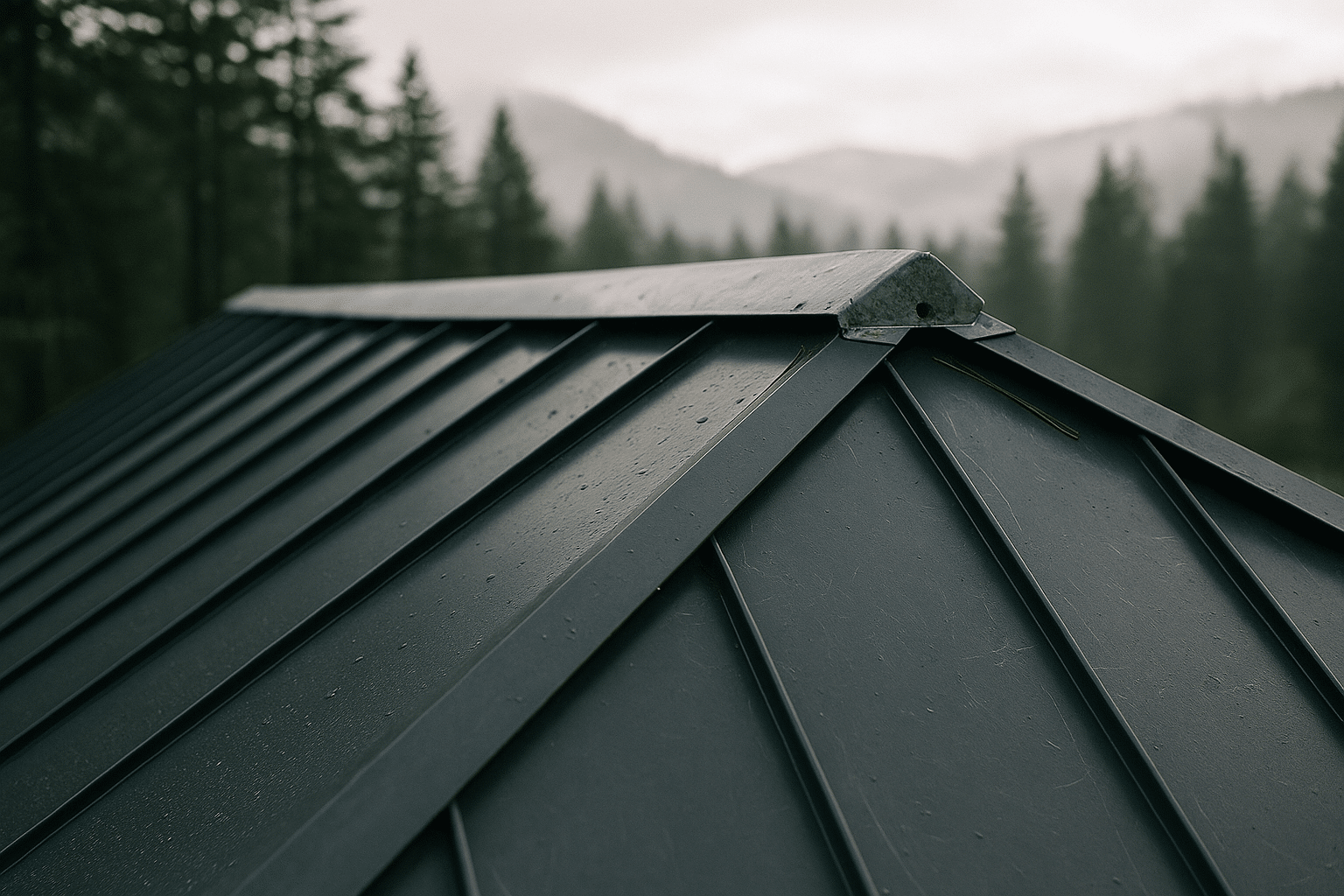

Durability and Safety: Why Steel Roofing Earns a Second Look

Steel roofing has a reputation for endurance that appeals to homeowners who prefer to replace a roof once in a generation rather than every decade or two. Properly specified and installed, many steel systems are expected to perform for several decades, often 40 years or more, thanks to a combination of protective metallic coatings, factory-applied finishes, and interlocking panel designs. Unlike materials that gradually dry out or lose granules, steel’s primary risks—corrosion and mechanical damage—are mitigated by coating chemistry, detailing, and good maintenance. In practice, durability is the product of material selection plus craft: the metal’s thickness (gauge), the type and thickness of the protective coating, and the quality of flashings and fasteners all matter as much as the panels themselves.

Safety is another area where steel roofing is frequently valued. Noncombustible by nature, many systems achieve high fire-performance classifications, a meaningful attribute for homes near wildfire zones or dense urban neighborhoods where embers can travel. Wind resistance is similarly strong when panels are seamed, clipped, or fastened according to engineering requirements; uplift ratings vary by panel profile and substrate, but well-detailed steel roofs are commonly tested for severe storms. Impact resistance can also be robust: stiffer panels, resilient underlayments, and proper fastening reduce the likelihood of punctures or blow-offs during hail or wind-driven debris events.

Climate performance illustrates steel’s versatility. In snowy regions, smooth panels can shed snow efficiently, reducing load duration and the potential for ice dams when ventilation and insulation are designed correctly. In coastal or industrial environments, corrosion risk becomes the central consideration: zinc-coated (galvanized) and aluminum–zinc alloy–coated steels serve different exposure categories, and finish systems add another layer of protection against salt spray and pollutants. Thoughtful detailing around penetrations—chimneys, skylights, and vents—prevents leaks and protects cut edges.

Beyond hard performance metrics, steel’s light weight—often about one to three pounds per square foot depending on profile—places less stress on rafters and trusses than heavy masonry tiles. That can be an advantage in seismic regions and may simplify retrofits on older structures. A few practical notes help anchor expectations:

– Lifespan depends on gauge, coating type, finish quality, and installation detail, not just the base metal

– Fire and wind performance come from tested assemblies; request documentation that matches your home’s exposure

– Corrosion protection should be selected for your climate and distance from the coast

In short, steel roofing delivers a compelling mix of longevity and safety, provided the system is chosen for the environment it will face and installed with attention to detail. When those pieces align, the result is a roof that feels calm under summer sun and steady when the forecast looks unruly.

Energy Efficiency and Environmental Footprint

Energy performance is often the quiet strength of steel roofing. Modern factory finishes can reflect a meaningful portion of solar radiation, lowering surface temperatures and helping reduce cooling loads. Depending on color and pigment technology, solar reflectance can range substantially; light, “cool” finishes tend to reflect more heat than darker tones, though even some deeper hues use pigments that reflect infrared wavelengths. Emittance—how readily a surface releases absorbed heat—also plays a role. When paired with proper attic ventilation and insulation, these characteristics can translate to noticeable summertime comfort and electricity savings.

While the exact percentage varies by climate and house design, studies and field data have reported cooling-energy reductions in the range of roughly 10–25% for homes that move from dark, heat-absorbing roofs to reflective metal assemblies with adequate attic airflow. The benefits are strongest in hot, sunny regions, but they are not limited to them. In mixed or cool climates, energy outcomes depend on the balance between summer heat rejection and winter solar gain. Because winter days are shorter and sun angles are lower, the penalty for reflectivity is typically smaller than the benefit gained in long, hot seasons, though insulation levels and air sealing ultimately dominate winter performance.

Environmental impact extends beyond utility bills. Steel is one of the world’s most recycled materials; many roofing panels contain recycled content, and the roof itself is recyclable at end-of-life. That circular pathway helps divert waste from landfills—a contrast with roofing products that are more difficult to reclaim. Lightweight panels also reduce transport energy per square of roof area compared with heavier options. Sustainability is holistic, so it’s wise to evaluate the whole assembly: substrate, underlayment, fasteners, and ventilation strategy all influence real-world performance.

Moisture management deserves attention because energy efficiency depends on a dry, well-ventilated enclosure. A continuous air barrier, balanced intake and exhaust ventilation, and high-quality underlayment work together to limit condensation risk. In humid climates, a vented air space beneath the panels or raised seam geometry can promote drying while maintaining the roof’s reflective benefits. A few practical takeaways help guide decisions:

– Choose color and finish based on both aesthetics and measured reflectance/emittance data

– Improve attic insulation and ventilation to capture the full benefit of a reflective roof

– Consider a vented assembly or rainscreen-style approach in humid or mixed climates

By treating the roof as a system—panels, finishes, underlayment, and airflow—you can unlock the efficiency potential that makes steel a notably frugal performer under strong sun.

Costs, Value, and the Long Game

Cost comparisons between steel roofing and more common alternatives hinge on timelines. Upfront, steel typically commands a higher installed price per square foot because panels, trims, and skilled labor add material and fabrication value. Prices vary by region, roof complexity, panel profile, and metal thickness, but many homeowners view steel as a capital project aimed at lifetime cost control rather than the lowest initial quote. That mindset changes the math: fewer tear-offs, fewer landfill fees, and less frequent disruption can matter as much as material cost.

To think clearly about value, model the total cost of ownership. Consider initial installation, periodic inspections, minor maintenance (such as sealant renewal at key transitions), and eventual end-of-life recycling or replacement of accessories. In many cases, steel roofs require relatively little routine care compared with materials that rely on granular surfaces or organic binders. That can translate into steady performance without a cycle of mid-life repairs. Where severe weather is common, steel’s resistance to embers, wind uplift, and hail can reduce the likelihood of storm-related replacements, helping protect both the structure and budgets over time.

Resale and insurance considerations can also enter the equation. While housing markets are local and nuanced, a durable, low-maintenance roof often contributes to buyer confidence and can support stronger curb appeal. In some regions, insurers offer incentives for impact-resistant or noncombustible roofing assemblies; availability and terms vary widely, so it’s worth asking agents about local programs and documentation requirements. Warranties add another layer of value: look for coverage that distinguishes between material coatings, substrate corrosion, and workmanship, and verify transferability if you plan to sell during the coverage period.

Because costs are context-specific, collecting detailed proposals is essential. Request line-item quotes that call out panel gauge, coating type, finish system, fastener strategy (exposed versus concealed), trim and flashing details, underlayment specifications, ventilation improvements, and any allowances for rotten decking or structural fixes. This level of clarity helps you compare apples to apples and prevents “surprise” change orders. A few budgeting pointers can sharpen decisions:

– Evaluate lifetime cost, not just initial price; include maintenance, potential repairs, and disposal

– Ask about regional incentives for reflective roofs or resilient assemblies, where applicable

– Build a contingency for wood repair, especially on older homes with hidden damage

Viewed through a multi-decade lens, steel roofing often presents a stable, predictable ownership profile. It’s an investment in fewer surprises overhead and a quieter line item in home upkeep.

Design, Comfort, and Climate Fit

Beyond spreadsheets, a roof sets the tone for a home’s personality. Steel excels here because it comes in profiles that range from crisp standing seams to textured, shingle-like panels that echo traditional looks. Color palettes are wide, and modern matte finishes can soften reflections for a refined, architectural feel. Texture matters too: subtle striations—shallow ribs rolled into panels—help reduce the visual ripple known as “oil canning,” especially on larger flat pans. Trim work around eaves, hips, and valleys contributes as much to the final appearance as the panels, so ask to see detail photos or mockups.

Comfort concerns often center on noise. The classic image of rain hammering metal belongs to uninsulated barns, not homes with sheathing, underlayment, and ceiling assemblies. In residences, the combination of wood decking, air spaces, insulation, drywall, and furnishings dramatically reduces sound transmission. Many homeowners report only a soft patter during downpours—if anything, an appealing soundtrack. If acoustic sensitivity is a priority, denser underlayments or sound-dampening membranes can further quiet the roof without altering exterior aesthetics.

Climate fit deserves a tailored approach. In hot, dry regions, reflective finishes and ventilated assemblies are straightforward choices. In snowy climates, steep pitches and smooth seams help snow release evenly, while ice-dam prevention hinges on insulation continuity and ridge-to-eave ventilation. In coastal zones, the conversation begins with corrosion exposure and continues with fastener selection, sealant compatibility, and edge treatments to protect cut metal. For areas prone to hurricanes or severe storms, panel geometry, clip spacing, and substrate attachment become central to resisting uplift.

Daily life offers practical considerations as well. Walking on panels requires care, and installers are trained to step in the right places to avoid denting thin pans; homeowners should limit foot traffic or consult the installer for safe paths. Add-on features—snow guards, integrated gutters, and mounting brackets for solar modules—are readily accommodated when planned in advance. Penetrations for vents and flues should be minimized and managed with purpose-made boots and flashings designed for thermal movement. Key planning notes include:

– Select profile, color, and striation patterns together to balance aesthetics and thermal movement

– Match coating and fasteners to the corrosion category of your site, especially near saltwater

– Coordinate snow retention and solar mounts during design to avoid ad hoc penetrations later

Approached thoughtfully, steel roofing can look at home on modern lines, farmhouse forms, or classic cottages, all while adding tangible comfort under real weather.

Conclusion: A Practical Path to Choosing Steel Roofing

Choosing a roof is both a technical decision and a lifestyle choice. Steel stands out as a resilient, low-maintenance option that can support energy goals, hold up under diverse climates, and deliver a clean, enduring look. Yet, like any building system, it performs to its potential only when specified and installed for the conditions it will face. The clearest path forward is deliberate: define your climate exposures, set performance priorities, and ask for documentation that aligns with those needs.

Use this practical checklist to organize the conversation with your contractor or designer:

– Exposure: wind speeds, wildfire risk, snow loads, and coastal salinity

– Materials: panel gauge, protective coating type (zinc or aluminum–zinc), and finish system

– Details: concealed versus exposed fasteners, clip spacing, and thermal movement accommodations

– Assembly: underlayment type, ventilation strategy, and attic insulation improvements

– Accessories: snow guards, gutters, and preplanned mounts for solar or service penetrations

– Paperwork: tested performance data, warranty terms, and maintenance guidance specific to your roof

For homeowners, the promise is practical rather than flashy: fewer roof worries over many seasons, steadier energy performance, and a curb appearance that doesn’t tire with time. For builders and property managers, steel simplifies lifecycle planning and reduces the churn of repeated replacements. If your goals include durability, safety, and efficiency without constant upkeep, steel roofing is among the most compelling options to put on your shortlist. With the right specification and a qualified installer, the roof over your head can shift from a recurring project to a dependable backdrop of daily life.